An interview with Alfredo Salvatori

03.2022

A talk with Alfredo Salvatori

Today, Salvatori is a design brand known the world over, enjoying a sustained period of growth as more and more clients discover its iconic, elegant products made primarily from natural stone.

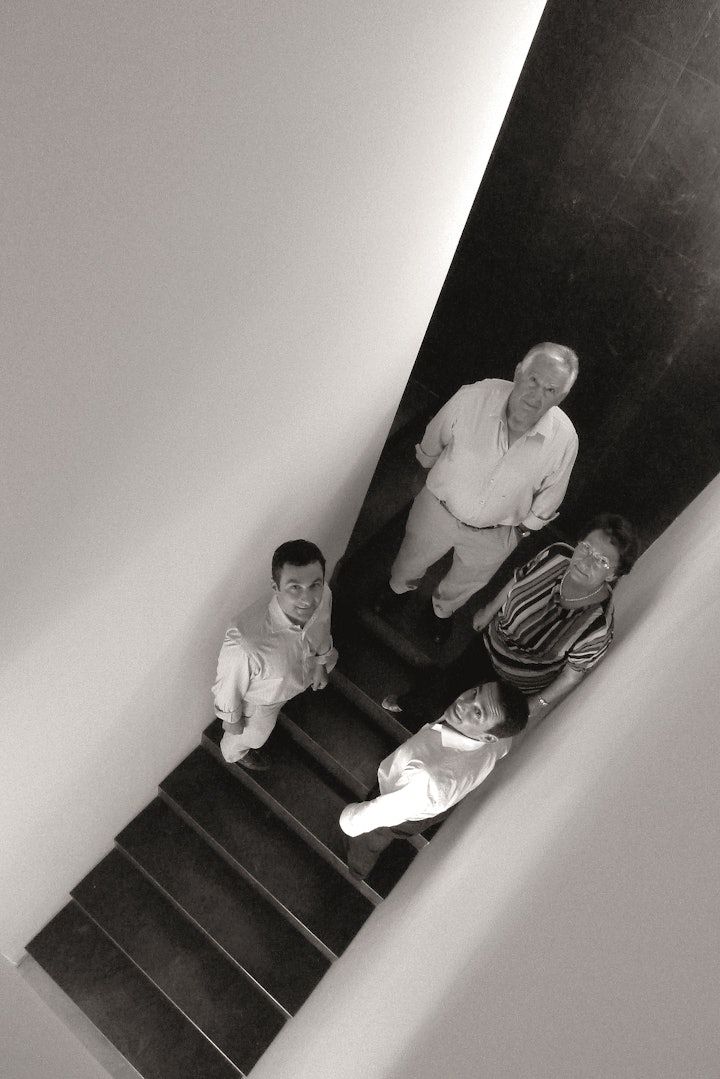

Considered a benchmark in the sector, the journey to this point was not always smooth, however. We sat down and chatted with Alfredo, company president and the father of CEO Gabriele, to hear his story and find out some of the challenges he faced in the past, as well as his insights into what helped create the foundation for today’s success.

Alfredo, you took over the company from your father in the 1970s. Could you tell us a little about how that came about?

My father started the company in 1946, along with a partner. At the beginning, they worked with timber but in the early 1950s when the marble market opened up, we diversified our production, working with both materials.

Innovation has always been ingrained in our family. I remember, for example, that our first original product in stone was the so-called splitface tile, sometimes described as a rustic tile.

For the first three years, nobody showed much interest in these tiles, but then they not only started selling like hot cakes, but other manufacturers began copying them. It was an incredible boom period for us, we were working 24 hours a day and in some territories we needed as many as three sales reps, without any of them stepping on each other’s toes.

During the Sixties, I graduated from high school, where I had met Maria, who would go on to become my wife. The two of us entered the family company. I was sent to Corsica to source timber and when I returned, I was told that in the meantime they’d purchased a marble sawmill and so, looking after that ended up being my job for the first few years. I ran all aspects of it and I remember that we managed to pay it off completely within two years, using our profits, whereas I just kept my lowly salary of 60,000 lire a month.

There were many technological innovations during those years and at a certain point, machines came along that could cut those bits of stone that had previously simply been thrown out.

We invested, but we ran up our fair share of debts at that time and so, in 1974, we dissolved the company and split it, with my father taking the stone side of the business and his partner keeping the timber part.

Given that I had spent the past decade or so immersed in the stone culture, together with my wife, I decided I would like to take control of the business. I talked with my brothers, who weren’t in the least interested in working in the stone sector, and so I purchased their shares too, and put my name above the door.

What were some of the challenges you had to face during your decades at the helm of Salvatori?

I ran the company for around 25 years, from 1974 to 2000, more or less, and in that time we definitely faced our share of challenges, and we also always tried things that others weren’t doing.

An enormous amount of analysis and very specific research went into every product and system we developed.

For example, I invented a closed-circuit water recycling system, not only to avoid wasting a precious natural resource, but also to reduce the impact of what we did on the environment. When you work with stone, you generate micro particles of dust and if you simply let them wash away, they end up creating a layer on river beds and this hinders the plants’ photosynthesis process and, eventually, damages the entire river ecosystem.

That invention was exclusive to Salvatori for a long time, but then was adopted by all the other Italian stone companies.

My wife looked after the administration and accounting side of things and she was simply brilliant at it.

Plus, she was the glue that held our family together, and I can put my hand on my heart and say it was most of all thanks to her that I managed to achieve what I did with this business.

1996 marked another challenge, when our sons joined the company fulltime. Gabriele has always been a visionary and he threw himself into the company, starting out in sales before becoming CEO. Guido takes after his mother and is more pragmatic, and with his economics degree and meticulous attention to law and regulations, came on board as CFO, looking after the financial side of the business. Playing to the strengths of every member of a team is one of the secrets to a successful business.

That was the moment we started to “go global” and it was Gabriele who drove that, with his creativity and his ability to see beyond the immediate frontiers and possibilities.

Another challenge was how to create a team where everyone felt they were an essential part of the company, and were happy to work with us, and work as though it was their business.

I decided the best approach was to hire young guys, just turned 18, and to teach them every aspect of the business. They learnt all the ins and outs of a trade, they had my trust, and in return, I received their gratitude and commitment. I really believe that trust, gratitude and continuous training are key to building lasting relationships.

What do you think are the secrets behind your success?

Without doubt, a meritocratic attitude, trust and gratitude have been important for our company. They meant that we could always have a long-term view of our employees and their training and the result is that everyone not only is appreciative, but also feels a sense of responsibility and carries out their work as though they weren’t an employee, but an owner.

This attitude meant that over the years we created a working environment that was both friendly and professional, where everyone lends a hand and supports each other.

Another important aspect that contributed to our success was definitely innovation and research. We invest a lot in research so that we can innovate not only in production but in all areas of the business. We aim to be as sustainable as possible, from packaging through to every day activities. We’ve banned plastic bottles, cups and so on, and use only glass water bottles, for example.

Innovation has always been at the heart of what we do.

When we bring a new product to the market or work on a project, we impose our own rules. That way we avoid creating unusable scraps or wasting material, and more importantly, it means clients have no choice. They have to accept the solution that is best for us, which is also, in the end, the best solution for them, because when they play by our rules, their project or product is executed more efficiently and in a smarter way.

We’re also looking for ways to improve our packaging. Because of the particular nature of stone, we’re more or less forced to use Styrofoam, but we’ve embarked on a collaboration with the Sant’Anna university in Pisa to develop edible packaging and that’s really exciting.